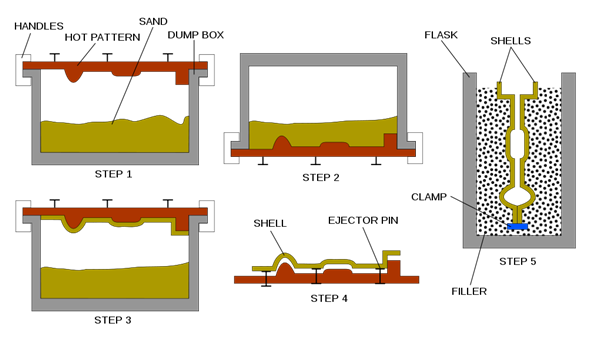

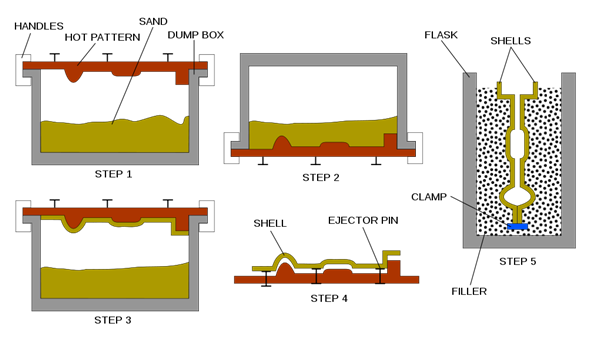

Image Source : Schematic of the shell molding process. Based on diagram from Degarmo, E. Paul; Black, J T.; Kohser, Ronald A. (2003), Materials and Processes in Manufacturing (9th ed.), p. 287. Wiley, ISBN 0-471-65653-4.

What is Shell Moulding Process?

-

In the shell moulding process the moulds and cores are prepared by mixing the dry free flowing sand with thermosetting resins and then heating the aggregate (mixture of fine sand (100-150 mesh) and thermosetting resins) against a heated metal plate.

-

Due to the heat, the resin cures, which causes the sand grains to get bonded with each other and it forms a hard shell around the metallic pattern.

-

The inside portion of the shell is the exact replica of the pattern against which the sand aggregate is placed before heating.

-

The shape and dimension of the inside portion of the shell thus formed is exactly the same as that of the pattern.

-

If the pattern is of two pieces then the other half of the shell is also prepared the same way.

-

Two halves of the shells prepared are placed together after inserting the core, if any, to make the assembly of the mould.

-

The assembly of the shell is then placed in a moulding flask and backing material is placed all around the shell mould assembly to give its assembly the sufficient strength.

-

Now the shell mould is fully ready for pouring the liquid metal.

Advantages

The shell process has several unique properties which makes it an important process in the foundries. These properties can be briefed as:

-

Excellent Surface Finish: Shell sand process has the ability to produce castings with excellent surface finish and capacity to produce very fine detail.

-

Dimensional Accuracy: The process has an ability to produce castings to tight dimensional tolerances. Due to this characteristic, machining allowance can be reduced which ultimately helps in reduction of the fettling and finishing costs. The shell process accommodates easily deep drawer patterns withless tapers than conversional production processes.

-

Hollow Cores: With the shell sands hollow cores and thin profile moulds can be possible. This characteristic gives economics in sand usage & ease of handling. Hollow cores increase the permeability hence usage of very fine sands is also possible.

-

Sand to Metal Ratio: This is a unique process thatgives hollow cores and thin walled moulds, which results in substantial weight reduction and material savings. The normal sand to metal ratio is 1:1 which is much lower than other processes.

-

Ease of Handling: The molds and cores made by shell molding have exceptional resistance to damage during storage and handling. They have a very high resistance to humidly and can be easily stored for long periods.

-

Resistant to Moisture Pickup: The shell process has higher resistant to moisture and can be stored in humid conditions for months together. The resin used in shell molding process is very stable and moisture resistant.

-

Excellent Flow-Ability: The dry coating on sand, gives better flowability and blowing ability compared to processes based on wet sand mixes. This property helps in producing intricate cores and moulds which canbe blown to a greater density. e.g. cores for water jacket.

-

Less Inclusions & High Thermal Stability: The shell sands are less prone to erosion by molten metal due to higher thermal stability of the phenolic resins. This unique characteristic helps in reducing defects like non-metallic burn-in and scabs etc.

-

Lesser Pattern Wear: As most of the patterns are made from cast iron, very little or no-wear is observed which results inhigher pattern life. This helps in producing large number of castings without much difficulty.

-

Longer Shelf Life: When properly stored, the shell sands have an indefinite shelf life hence these sands can be stored and used as needed in the foundry.

Reference : "Module-2 - ADVANCED METAL CASTING PROCESSES (Lecture-9 & 10)." NPTEL (IIT-Roorkee). Web. 1 Oct. 2015